Lesson Applied

- Darren Sciberras

- Jul 14, 2025

- 4 min read

We have all heard the phrase "I've learnt my lesson". Some big organisations and corporate hot dogs even love to have a 'Lessons Learnt' database, coupled by a 'team alignment' weekend at some fancy resort. Then talk through "what did we learn? "What should we do?", or have a ping pong contest seeing who can use the most buzz words in one sentence. Yet too often some of these lessons are repeated because they were never properly applied.

Ultimately a 'Lesson Learnt' is WORTHLESS until it is APPLIED.

Evolving your day to day process to incorporate the lesson, putting actual steps and systems in place to minimise the risk of the issue ever reoccurring is the real key. Learning the leason is only the beginijng, applying it is the gold and where the real work is.

Recently we had a few jobs in that really hit home on this.

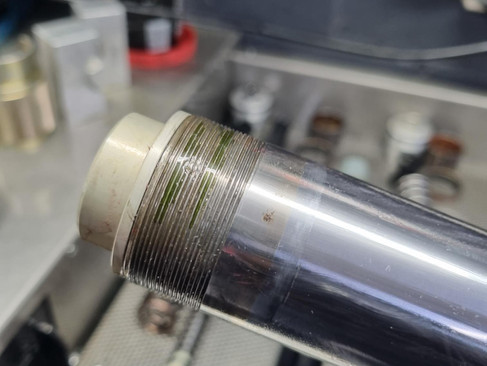

You may not be aware but almost all fork tubes are secured to their bases by a thread. In many cases their only locking mechanism is permanent thread locker. Permanent thread locker is an amazing agent, it works very well. However only if applied properly followed by how it is dealt with during fork upgrades and it's integrity is checked at the appropriate service interval.

Way back in 2007....gee that's 18 years ago now! We had an incident where Daz literally 'lost the front' in a high speed, 4th gear crash at QLD Raceway.

'The post crash analysis uncovered clear signs of an unnoticed, developing fatigue crack that eventually sheared. Further analysis showed it was due to a loose mating between the fork tube and base.'

More investigations and experience lead to the realisation that some fork designs, models and modifications are prone to this type of failure. Not super common but also not that uncommon.

From that very point forward, a check of the tube and base mating integrity has been conducted on every single Race Center fork service or upgrade. It was incorporated into our checks and checklists straight away without the need for a weekend at a fancy resort. It has now been done on thousands of jobs over the last 18 years.

In the most recent case we uncovered, it was clear the previous upgrade (done elsewhere) just weren't done to the standard it should have been. It was a disaster waiting to happen. Thankfully, this time is was completely avoided.

Whenever a fork is serviced, this is one of many checks that needs to be done. Yet far too often it is not even specified in a service manual and many technicians are not even aware of the requirement to do so.

You may be surprised to know, a Race Center fork service or upgrade has between 37 and 92 check points, PER LEG, depending on the fork type and the scope of the upgrade, yep that many. It is a lot and does take time.

Fork servicing is a lot more than changing seals. Ensuring everything is working properly and is in a fit state is not just important from a safety standpoint, but also a performance standpoint.

Things like air gap volume, spring integrity after many km's or laps of life, correct bleeding procedures, wear limits on moving and sliding parts... the list goes on. The attention to detail matters.

It's rare, however there are times the occasional inquiry results in "how much? just to change seals?" followed by a scoff. Little do they know. 18 years on from that incident, not one fork service or upgrade has skipped this vital step.

Another Example of Lessons Applied

In another example of lessons applied is smog block off plates, wiring under the airbox and in close proximity to the radiator fans. Especially where aftermarket units are fitted such as quickshifter or blippers.

Manufacturing standards these days are simply woefull in some case. Many aftermarket smog block off plates for example have very sharp edges due to poor manufacturing. Sharp edges and delicate wiring do not mix! Especially as most of the wiring in that area is critical to the bike running. If the sharp edge penetrates the wiring sheath, a short will occur and the bike will instantly cut out.

If this were to happen on a race track, at high speed down the straight, with another bike right behind getting a slipstream? Well you don't have to use much imagination to realise just how dangerous and catastrophic this could be.

'In this case, thankfully we did not need a big incident to apply the lessons. We had a bike cut out at Winton many years ago and uncovered what was happening. From that point the following procedure was introduced. Wiring - Block Off Plates'

This was an addition to the pre-existing procedure that is carried out on every single Race Center job that involves working in this area. A second technician must quality check the wiring routing and securing before the airbox is reinstalled. This particular procedure was also introduced in 2007 when we first discovered that Race R6s were prone to the fans cutting wiring under the airbox.

Learnt on the Racetrack yet applies to everyday life

Regardless of your industry or application. The next time an incident occurs that you could learn from, ask yourself this very one thing..... "Is that a lesson we've learnt? OR "Is it a lesson we have applied? Have we actually done the work to minimise the risk of it ever occurring again" There is a massive difference.

Comments